Views: 0 Author: Site Editor Publish Time: 2025-09-09 Origin: Site

Selecting the correct fitting size for your propane hose ensures safe operation and reliable connections with your appliances. You will often encounter sizes like 3/8", 1/4", and 1/2" NPT, along with POL and ACME types. Before installing, check your hose and appliance for any labels or markings to confirm compatibility. Using the right fitting helps you prevent leaks and keeps your equipment working properly.

Select the right fitting size for your propane hose to ensure safety and prevent leaks.

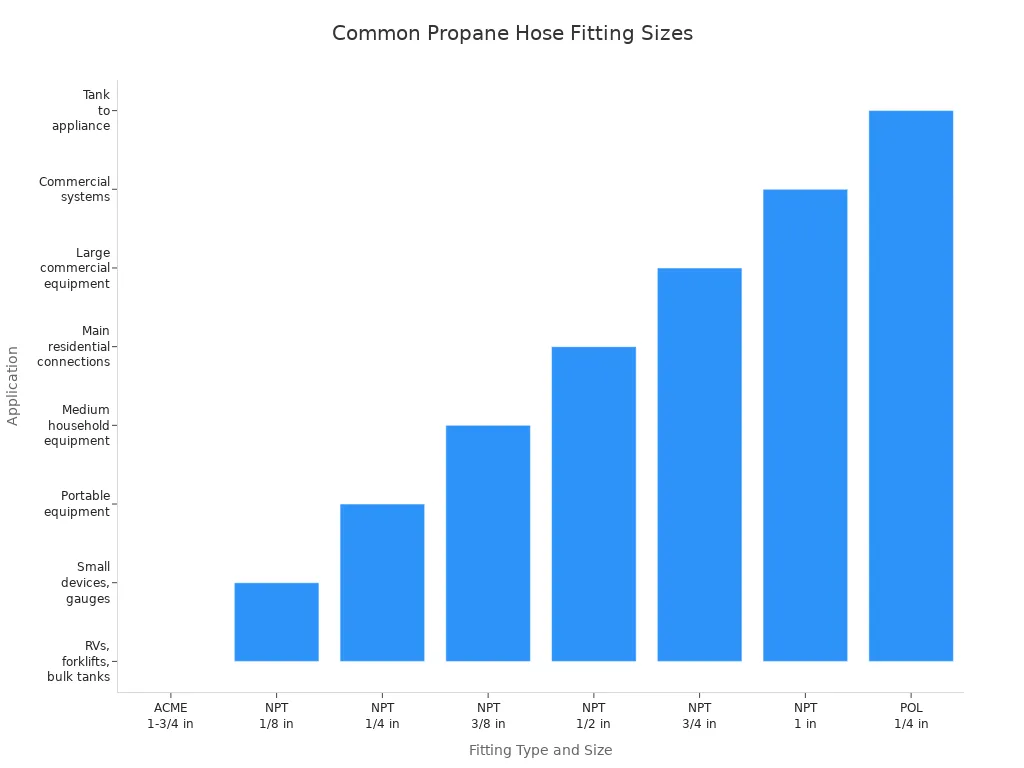

Common sizes include 3/8 inch for grills and RVs, 1/4 inch for small appliances, and 1/2 inch for high-capacity setups.

Understand thread types like NPT, POL, and Quick Connect to ensure compatibility with your appliances.

Always measure fittings accurately using calipers and thread gauges before purchasing replacements.

Inspect hoses and fittings regularly for wear and replace them every 3 to 5 years to maintain safety.

Use certified fittings with CSA or UL marks to ensure they meet safety standards.

Follow proper installation techniques, including using thread sealant for NPT fittings to prevent leaks.

Consult manufacturer specifications for your appliances to confirm the correct fitting type and size.

When you select a propane hose, understanding the fitting size and thread type is essential. The right fit ensures a secure connection and prevents leaks. Let’s break down the most common sizes and thread types you will encounter.

You will find 3/8 inch fittings on most residential and commercial propane hoses. This size works well for grills, RV appliances, and portable heaters. The 3/8 inch fitting often uses NPT threads, which provide a tight seal when paired with the correct thread sealant. Many propane hose assemblies for outdoor cooking and camping use this size because it balances gas flow and safety.

The 1/4 inch fitting appears on smaller appliances and extension hoses. If you use a compact grill, tabletop heater, or a torch, you may notice this size. It is ideal for low to medium gas flow applications. The 1/4 inch fitting can also serve as a connector for adapters that link 1lb cylinders to larger tanks.

You will encounter 1/2 inch fittings in high-capacity or industrial propane hose setups. These fittings handle higher gas volumes, making them suitable for large heaters, commercial stoves, or bulk tank connections. The 1/2 inch size often uses NPT threads and requires careful installation to ensure a leak-free seal.

NPT stands for National Pipe Thread. You will recognize NPT fittings by their tapered threads, which require a thread sealant to prevent leaks. Most regulators and propane hoses use NPT threads, except for some auto-changeover regulators. NPT threads are common in both residential and commercial propane systems.

POL fittings feature internal threads and require a wrench for tightening. You will find POL connections on many propane tanks, especially those ranging from 40 lb to 100 lb. The left-hand threading design helps prevent accidental loosening, which reduces the risk of leaks. POL fittings remain a standard for connecting propane hoses to larger cylinders.

Quick Connect fittings allow you to attach or detach your propane hose rapidly without tools. These fittings are popular on grills, camping stoves, and RV setups. The push-to-connect mechanism includes a locking system that ensures a tight, secure seal. Quick Connect fittings make switching appliances fast and safe, especially when you need to move equipment frequently.

Tip: You can easily distinguish between POL and Type 1 (ACME) fittings by their appearance. Type 1 fittings have a colored connector for hand-tightening, while POL fittings use internal threads and require a wrench.

| Size | Thread Type | Typical Application | Special Features |

|---|---|---|---|

| 3/8 inch | NPT, Quick Connect | Grills, RVs, portable heaters | Most common for residential propane hose |

| 1/4 inch | NPT, Flare | Small appliances, torches, adapters | Used for low/medium flow; connects 1lb cylinders |

| 1/2 inch | NPT | Large heaters, commercial stoves | Handles higher gas volume |

| 1"-20 (POL) | POL | 20lb+ tanks, bulk adapters | Internal threads, wrench required, leak prevention |

| Type 1 (ACME) | ACME | Modern tanks, hand-tightenable connections | Colored connector, tool-free installation |

| Quick Connect | Quick Connect | Grills, RVs, camping stoves | Push-to-connect, locking system for safety |

You should always match the fitting size and thread type to your appliance and propane hose. This practice ensures safety and optimal performance for your gas-powered equipment.

Accurate measurement of your propane hose fittings ensures a safe and leak-free connection. You need to know both the size and the thread type before purchasing or replacing any component.

To measure propane hose fittings, you should gather the following tools:

Calipers: Use these to measure the inside diameter (ID) of hoses and the outside diameter of fittings.

Thread gauge: This tool helps you determine the thread pitch and diameter.

Size chart: Reference charts match your measurements to standard fitting sizes.

Flashlight: Good lighting helps you see threads and markings clearly.

Tip: Fittings are named for the hose they connect to, not their internal dimensions. Always measure the hose and fitting together for accuracy.

Follow these steps to measure your propane hose fitting size and thread type:

Identify the Fitting Type

Examine the fitting. Look for distinguishing features such as internal threads (POL), tapered threads (NPT), or a flared end (flare fitting).

Measure the Fitting Size

Use calipers to measure the outside diameter of male threads or the inside diameter of female threads. For flare fittings, measure the outside diameter of the threaded portion.

Consult Size Charts and Markings

Compare your measurements to a propane fitting size chart. Check for any size markings stamped on the fitting itself.

Verify Compatibility

Ensure the inside diameter of the fitting’s female end is larger than the outside diameter of the hose’s male end. This guarantees a secure connection.

Double-Check with Manufacturer Specs

Review the manufacturer’s specifications for your propane hose and appliance. Confirm that your measurements match the recommended fitting size and thread type.

Recognizing thread types and fitting styles is essential for proper installation. You can distinguish between male and female fittings and identify whether you have NPT or flare threads.

| Type | Characteristics |

|---|---|

| Male | Features external threads designed to engage with internal threads of female fittings. |

| Female | Characterized by internal threads that receive and engage with external threads of male fittings. |

| Key | Male fittings have external threads; female fittings have internal threads, dictating their connection. |

| Feature | Flare Fittings | NPT Fittings |

|---|---|---|

| Thread Design | Non-tapered, uses a flared end for sealing | Tapered threads that compress to seal |

| Sealing Mechanism | Seals by compressing the flared end against a surface | Seals through compression of the threads |

| Size Compatibility | Cannot substitute for NPT fittings of the same nominal size | Cannot substitute for flare fittings of the same nominal size |

Note: Calipers and thread gauges provide precise measurements for both the inside diameter and thread pitch. Accurate sizing ensures your propane hose fits securely and safely.

You should always check for male or female threads before buying new fittings. Flare fittings use a flared end for sealing, while NPT fittings rely on tapered threads. Never substitute one type for another, even if the nominal size matches.

Choosing the right fitting for your propane hose depends on the appliance you want to connect. Each type of appliance uses specific fitting sizes and thread types to ensure safety and efficiency.

You often connect grills to propane tanks using Type 1 (ACME) fittings. These fittings measure about 1-3/4 inches and allow you to hand-tighten the connection. Many modern grills use quick-connect fittings for easy setup and removal. Some portable grills require adapters to connect to disposable cylinders.

Heaters, especially portable models, use a mix of fitting types. You may find NPT threads on larger heaters, which provide a secure seal for high-pressure applications. Smaller heaters often use disposable cylinder ports with 1-20'' female threads. This design supports quick changes and safe operation in outdoor settings.

RV propane systems rely on a combination of POL and quick-connect fittings. POL fittings connect to larger tanks and require a wrench for tightening. Quick-connect fittings, available in sizes like 3/8 inch and 1/2 inch, let you switch appliances quickly. Many RV setups use brass tee adapter kits to split propane flow between multiple devices.

Propane torches typically use NPT or disposable cylinder port fittings. High-pressure torches need secure connections, so you often see 1-20'' male pipe threads. Some torches use specialty adapters to connect to both small and large cylinders, giving you flexibility for different jobs.

Tip: Always check the manufacturer’s specifications for your appliance before selecting a fitting. Using the correct fitting type and size prevents leaks and ensures safe operation.

You can use the following chart to match fitting types and sizes to common propane appliances. This chart helps you select the right connection for your setup.

| Appliance | Fitting Type | Common Size | Description |

|---|---|---|---|

| Grill | Type 1 (ACME), Quick-Connect | 1-3/4 inches, 3/8 inch | Hand-tighten for large tanks; quick-connect for portable grills |

| Heater | NPT, Disposable Cylinder Port | 1-20'' male/female | Secure seal for high-pressure; easy change for small heaters |

| RV | POL, Quick-Connect, Brass Tee | 1-20'', 3/8 inch | Wrench-tighten for tanks; split flow for multiple appliances |

| Torch | NPT, Disposable Cylinder Port | 1-20'' male/female | High-pressure connection; flexible for different cylinder sizes |

You should always use the correct fitting for your appliance. This practice protects you from leaks and ensures efficient gas flow.

You may need specialty adapters to connect mismatched fittings or expand your propane system. Common options include:

Quick-connect fittings in sizes like 3/8 inch, 1/2 inch, and 3/4 inch for rapid appliance changes.

Type 1 (ACME) adapters for connecting large tanks to various appliances.

POL to Type 1 adapters for switching between different tank types.

Quick disconnect to NPT adapters for joining hoses with different thread styles.

Brass tee kits for splitting propane flow to multiple devices in RVs or campsites.

Note: Always verify pressure ratings and flow capacities before installing adapters. Using the correct adapter maintains safety and performance.

You can rely on this compatibility guide to match your propane hose to grills, heaters, RVs, and torches. Specialty adapters give you flexibility for unique setups and multi-appliance use.

When you select propane hose fittings, you must prioritize safety. Certified fittings help you avoid accidents and ensure reliable performance. Look for these certifications:

CSA (Canadian Standards Association)

UL (Underwriters Laboratories)

These certifications confirm that the fittings meet strict safety standards. You should also check the pressure rating and material of each hose. The table below shows recommended ratings and materials for different applications:

| Application Type | Pressure Rating (PSI) | Flow Rate (BTU/hr) |

|---|---|---|

| Standard Appliances | ~0.4 PSI | 40,000 - 60,000 |

| High-Output Devices | Higher than 0.4 PSI | 100,000 or higher |

| Gas Grills | ~0.4 PSI | 40,000 - 60,000 |

| Larger Outdoor Burners | Higher than 0.4 PSI | 100,000 or higher |

Materials Used: Rubber, thermoplastic, and reinforced synthetics offer durability and flexibility. You should always choose hoses made from these materials for safe propane transport.

Tip: Always verify that your hose and fittings display CSA or UL certification marks before installation.

Proper installation prevents leaks and keeps your propane system safe. You should follow these best practices:

Inspect hoses for wear, cracks, or leaks before installation.

Store hoses in a cool, dry place away from sunlight and heat.

Test for leaks regularly using soapy water or a leak detector.

Use the correct hose length and fitting type to avoid stress and corrosion.

Read the manufacturer's instructions carefully for secure fitting.

Install restraining cables if your equipment moves frequently.

Hire a licensed professional if you feel unsure about the installation process.

Safety Reminder: Never force a fitting or substitute one type for another. Always match the fitting size and thread type to your appliance.

You must replace propane hoses and fittings when you notice signs of damage or aging. Common indicators include:

Visible cracking or stiffness in the hose.

Difficulty connecting fittings or signs of corrosion.

Leaks detected during regular inspections.

Stainless steel braided hoses should be replaced every 2-3 years due to hidden rubber components that may crack.

Experts recommend replacing propane hoses every 3 to 5 years, even if you do not see visible damage. Environmental exposure and frequent use can shorten the lifespan. The table below shows reported lifespans from users:

| User Experience | Reported Lifespan |

|---|---|

| User 1 | 10 years |

| User 2 | 5 years |

| User 3 | 5 years |

| User 4 | 3 to 5 years |

Note: Regular replacement and inspection keep your propane system safe and efficient. Do not wait for a leak or failure before taking action.

You may encounter several problems when working with propane hose fittings. Recognizing these issues early helps you maintain a safe and efficient propane system. Here are the most frequent challenges:

Leaks at Connection Points: Gas leaks often occur where the hose meets the tank or appliance. Damaged O-rings, worn gaskets, or improper sealing can cause these leaks.

Cross-Threading: If you misalign the threads during installation, you risk cross-threading. This mistake can damage the fitting and create a poor seal, leading to leaks.

Mismatched Fittings: Using the wrong size or type of fitting prevents a secure connection. Always check compatibility before installation.

Worn or Leaky Gaskets: Older tanks and hoses may have gaskets that degrade over time. This wear can result in persistent leaks.

Improper Sealing Techniques: Failing to use the correct sealing method, such as gas-rated tape or pipe dope, can allow gas to escape.

Sharp Hose Angles: A hose bent at a sharp angle may leak at the connection point. Ensure the hose runs smoothly without kinks.

Tip: Always inspect the hose and fittings for visible damage before connecting. Replace any worn components to prevent leaks.

If you discover a leak in your propane hose fitting, you must act quickly and follow proper troubleshooting steps. Use the following process to address leaks safely:

Check Connection Size

Confirm that the hose and fitting sizes match. Incompatible sizes often cause leaks.

Inspect for Cross-Threading

Examine the threads for signs of misalignment. If you notice cross-threading, disconnect and realign the fitting.

Avoid Over-Tightening

Tighten brass fittings gently. Over-tightening can strip threads and worsen leaks.

Use Proper Sealing Materials

Apply gas-rated tape or pipe dope to threaded connections. Ensure the product is approved for propane use.

Perform a Bubble Test

Mix soapy water in a spray bottle. Spray the solution on all joints and fittings. Watch for bubbles, which indicate a leak.

Replace Damaged Parts

If you find a damaged hose, gasket, or O-ring, replace it immediately. Consider using a longer hose to avoid sharp bends.

Test Regularly

Check for leaks before each use. Routine inspections help you catch problems early.

⚠️ Safety Precautions:

If you suspect a gas leak, leave the area immediately. Put out any open flames and avoid using electrical switches. Shut off the main gas supply valve if it is safe to do so. Open windows as you exit to help disperse the gas. Schedule a professional inspection of your propane system to ensure all leaks are fixed.

| Step | Action | Tools Needed |

|---|---|---|

| Inspect fittings | Look for damage, wear, or misalignment | Wrenches, flashlight |

| Seal connections | Use gas-rated tape or pipe dope | Teflon tape, pipe dope |

| Detect leaks | Perform bubble test | Spray bottle, soapy water |

| Replace components | Install new hose, gasket, or O-ring | Replacement parts |

You protect your safety and equipment by following these troubleshooting steps. Regular maintenance and careful installation keep your propane system running smoothly.

You can find propane hose fittings at many local hardware stores and home improvement centers. Stores such as Home Depot, Lowe’s, Ace Hardware, and Tractor Supply carry a wide selection of propane hoses and fittings. These retailers offer the advantage of in-person assistance. You can ask staff for help with sizing and compatibility. You also have the opportunity to inspect the fittings before you buy.

When you visit a local store, check the packaging for clear labeling. Look for the fitting size, thread type, and certification marks such as CSA or UL. These details help you confirm that the product meets safety standards. You should also examine the material. Rubber hoses work well for most residential uses. All-corrugated metal hoses provide extra protection against gas diffusion in high-demand or industrial settings.

Tip: Bring your old hose or fitting to the store. Compare it directly with new products to ensure a perfect match.

Online retailers offer a broad range of propane hose fittings. You can shop from the comfort of your home and access detailed product specifications. Many reputable brands sell certified fittings online. You should always choose trusted sellers to guarantee quality and safety.

Popular online retailers for propane hose fittings include:

Amazon

Flame King

PropaneFitting.com

Walmart

Home Depot (online)

Flame King stands out for its high-quality propane hoses and fittings. Their products undergo rigorous testing to meet industry safety standards. You can rely on their hoses for durability and efficient propane transfer.

When you shop online, review product descriptions carefully. Confirm the fitting size and thread type. Check for certification marks and read customer reviews. Reliable sellers provide clear information about pressure ratings and material properties.

| Factor | Description |

|---|---|

| Proper Installation | Ensures safety and efficiency in propane transfer. |

| Material Properties | Different materials affect performance and safety; e.g., rubber vs. PTFE. |

| Safety Standards | Products are tested to meet industry safety standards to prevent leaks and ensure performance. |

Understanding material properties is crucial for your specific application. Rubber and PTFE hoses may allow some gas diffusion, which can lead to pressure drops and safety hazards. All-corrugated metal hoses eliminate this risk and offer superior protection.

Note: Propane hoses and fittings play a vital role in safe and efficient propane transfer. They help prevent leaks and maintain correct pressure, which is essential for smooth appliance operation.

You should always verify the certification and compatibility of any fitting before purchase. Whether you buy locally or online, prioritize safety, material quality, and proper sizing. This approach ensures your propane system works reliably and safely.

You must identify the correct propane hose fitting size and thread type to ensure safe and reliable connections.

Learn about fitting types such as NPT and Quick-Connect.

Measure the thread’s outside diameter and compare it to a pipe size chart.

Inspect fittings regularly and follow local safety codes.

Choosing certified, high-quality hoses and fittings protects your system.

| Safety Benefit | Description |

|---|---|

| Consistent gas flow | Regulator reduces high-pressure propane to a safe level, preventing sudden bursts of flame. |

| Prevent gas leaks | Ensures correct propane supply, minimizing the risk of dangerous gas leaks. |

If you feel uncertain about selection or installation, you should consult a propane professional or the equipment manufacturer for guidance.

You will find 3/8 inch NPT as the most common fitting size for residential grills, heaters, and RVs. This size offers reliable gas flow and easy compatibility with many appliances.

You can check for markings or use a thread gauge. NPT threads look tapered, while POL threads have internal left-hand threads. Quick Connect fittings feature a push-to-connect design.

No, you should not mix fitting sizes. Always match the fitting size to your hose and appliance. Using mismatched sizes can cause leaks and unsafe connections.

You use POL fittings to connect propane hoses to larger tanks, such as 20lb or 100lb cylinders. These fittings require a wrench for tightening and provide a secure, leak-resistant seal.

You should inspect hoses yearly and replace them every 3 to 5 years. Replace immediately if you see cracks, corrosion, or leaks. Regular replacement keeps your system safe.

You need thread sealant for NPT fittings. Use gas-rated tape or pipe dope. Do not use sealant on flare or quick-connect fittings, as they seal by compression.

Yes, you can use a brass tee adapter kit. This kit splits propane flow safely to multiple appliances, such as grills and heaters, especially in RV setups.

You can buy certified fittings at hardware stores, RV supply shops, and online retailers like PropaneFitting.com or Amazon. Always check for CSA or UL certification before purchasing.